Skanska and Anglian Water’s Everton wetland: design and process notes for engineers

Reviewed by Tom Sullivan

First reported on New Civil Engineer

30 Second Briefing

Skanska has completed Anglian Water’s first integrated constructed treatment wetland at Everton Water Recycling Centre in Bedfordshire, designed to strip phosphorus and iron from final effluent using a nature‑based flow path rather than chemical dosing. The wetland forms part of the WRC outfall stream, using engineered reed beds and controlled hydraulic residence times to polish treated wastewater before discharge. For civil and water engineers, the scheme signals growing scope for low‑energy, passive treatment trains to meet tightening nutrient consents on small to medium works.

Technical Brief

- Facility is located at Everton Water Recycling Centre in Bedfordshire, serving a rural catchment.

- Nature‑based treatment train is configured as a constructed wetland rather than conventional tertiary plant.

- Wetland layout is designed to target both phosphorus and iron removal in a single flow path.

- Passive treatment approach reduces reliance on chemical dosing infrastructure, storage and delivery logistics.

Our Take

Skanska’s role at Everton Water Recycling Centre in Bedfordshire sits alongside its heavy civil work on HS2’s Euston tunnels and the Clifton railway bridge, signalling that the contractor is now pairing large transport schemes with higher‑profile environmental infrastructure in the United Kingdom.

Within our Environmental category, Anglian Water’s constructed wetland adds to several sustainability‑tagged pieces where UK asset owners are trialling nature‑based or low‑carbon solutions, which can influence how future water recycling centre upgrades are specified and procured.

For Anglian Water, piloting a constructed treatment wetland at a live WRC in Bedfordshire is likely to become a reference case when negotiating permits and performance standards with regulators on other rural sites, especially where conventional process expansions face footprint or community constraints.

Prepared by collating external sources, AI-assisted tools, and Geomechanics.io’s proprietary mining database, then reviewed for technical accuracy & edited by our geotechnical team.

Related Articles

Related Industries & Products

Construction

Quality control software for construction companies with material testing, batch tracking, and compliance management.

Mining

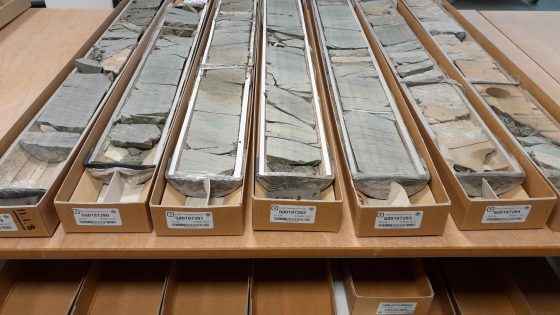

Geotechnical software solutions for mining operations including CMRR analysis, hydrogeological testing, and data management.

CMRR-io

Streamline coal mine roof stability assessments with our cloud-based CMRR software featuring automated calculations, multi-scenario analysis, and collaborative workflows.

HYDROGEO-io

Comprehensive hydrogeological testing platform for managing, analysing, and reporting on packer tests, lugeon values, and hydraulic conductivity assessments.

GEODB-io

Centralised geotechnical data management solution for storing, accessing, and analysing all your site investigation and material testing data.