Momentum Technologies dual-track US REE processing: design and scale-up notes for engineers

Reviewed by Tom Sullivan

First reported on MINING.com

30 Second Briefing

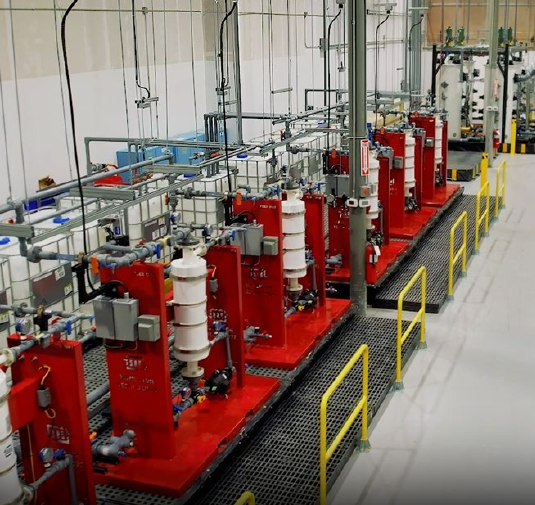

Momentum Technologies is commissioning what it claims is the world’s first dual-track demonstration plant near Dallas able to process both rare earth elements and lithium-ion battery materials using its proprietary membrane solvent extraction (MSX) system. MSX replaces football-field-scale solvent extraction circuits and kerosene with compact membrane reactors operating at moderate temperature and pressure, designed to cut footprint, energy use and time-to-commission for REE and battery-material refineries. The company is also progressing a 2,000 t/y commercial battery materials plant in Ohio and says its technology could ultimately support 20–50% of US rare earth processing capacity.

Technical Brief

- MSX replaces kerosene-based solvent extraction with compact membrane reactors running at room or moderate temperature/pressure.

- Traditional solvent extraction layouts described as “football-field-sized”, indicating order-of-magnitude footprint reduction with MSX.

Our Take

With Momentum Technologies’ MSX process projected to support 20–50% of US rare earth processing capacity, any successful scale-up in Texas would materially reduce the leverage of single-asset producers like Mountain Pass in California and change how offtake and pricing risk are allocated in US magnet supply chains.

The presence of the US Department of Energy and the Export-Import Bank of the United States across this piece and our other critical minerals coverage signals that US policy support is now spanning both ends of the chain: early-stage recycling/processing technologies in Texas and large upstream nickel projects such as Ardea’s Kalgoorlie development in Australia.

Linking US-based rare earth and battery materials processing to Ardea Resources’ Kalgoorlie nickel project and Argentine lithium in the same time horizon (mid-2026 to early 2027) suggests OEMs could soon structure multi-jurisdictional sourcing strategies that blend primary supply from Australia and Argentina with US recycling to meet domestic content and resilience targets.

Prepared by collating external sources, AI-assisted tools, and Geomechanics.io’s proprietary mining database, then reviewed for technical accuracy & edited by our geotechnical team.

Related Articles

Related Industries & Products

Mining

Geotechnical software solutions for mining operations including CMRR analysis, hydrogeological testing, and data management.

CMRR-io

Streamline coal mine roof stability assessments with our cloud-based CMRR software featuring automated calculations, multi-scenario analysis, and collaborative workflows.

HYDROGEO-io

Comprehensive hydrogeological testing platform for managing, analysing, and reporting on packer tests, lugeon values, and hydraulic conductivity assessments.

GEODB-io

Centralised geotechnical data management solution for storing, accessing, and analysing all your site investigation and material testing data.