Transition Metal copper microbe additive: recovery and scale-up notes for heap leach engineers

Reviewed by Tom Sullivan

First reported on MINING.com

30 Second Briefing

Transition Metal Solutions has raised an oversubscribed $6 million seed round to scale a chemical additive that activates native heap microbes, lifting copper recovery from low‑grade sulphide ores without new bioreactors, inoculation plants or changes to existing irrigation and leach flowsheets. Site-specific formulations, designed using metagenomic analysis of each orebody, have pushed lab recoveries on primary sulphides from roughly 60% to about 90% and delivered in situ acid generation with leach rates around three times typical industry performance on refractory, high‑carbonate ores. Three‑metre column pilots scheduled for early 2026 aim to prove consistent, controllable performance at industrial scale, targeting both current heaps and large stockpiles of uneconomic sulphide ore.

Technical Brief

- Additive is dosed into existing heap irrigation solution as a purely chemical product, not live culture.

- Site characterisation uses metagenomic profiling of each orebody’s microbial community before any formulation design.

- Platform targets in-heap functions: sulphide oxidation, ferrous/ferric iron cycling and metal solubilisation pathways.

- Approach deliberately avoids culturing microbes; >99% of heap organisms assumed unculturable under lab conditions.

- No inoculation plants, bioreactors or parallel biological systems are required, reducing capex and operational complexity.

- Regulatory burden is lower because no new organisms are introduced, only conditions for native microbes are modified.

- For operators, main integration task becomes upstream analytical work and dosing control, not redesign of heap flowsheets.

Our Take

With South Australia’s copper exports recently topping $3 billion on record prices, any proven uplift in sulfide-ore recoveries from Transition Metal Solutions’ microbes could materially extend mine lives at assets like BHP’s Olympic Dam and defer the need for higher-cost greenfield copper projects.

The oversubscribed $6 million seed round backed by investors such as BMW AG’s i Ventures and Breakthrough Energy LLC signals that downstream OEMs and climate-focused funds are starting to treat copper and other critical minerals processing innovations as strategic bottleneck technologies rather than niche process tweaks.

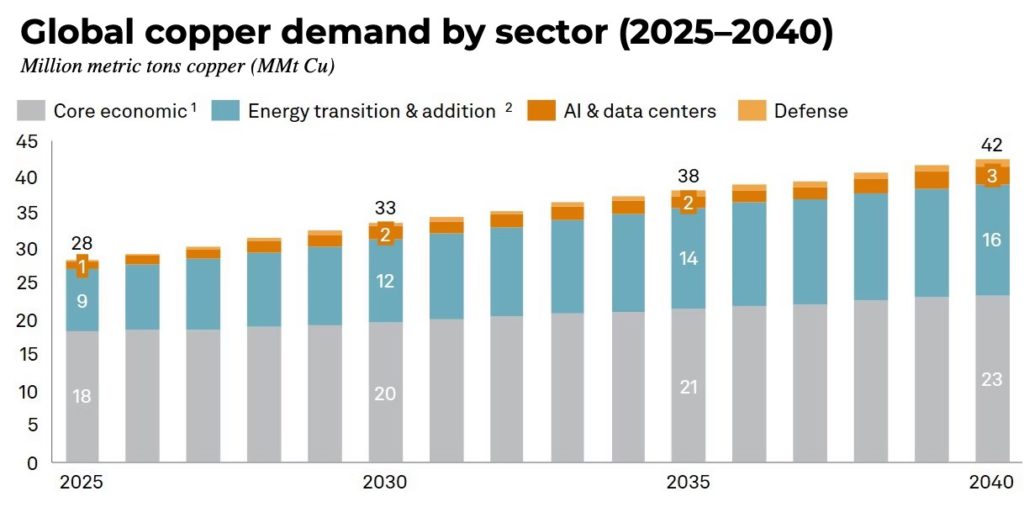

Given that roughly 80% of remaining copper reserves are sulfide ores with typical recoveries often below 60%, the reported threefold leaching-rate increase positions this approach as a potential alternative to large capital-intensive concentrator expansions, especially in permitting-constrained jurisdictions like the United States and Canada.

Prepared by collating external sources, AI-assisted tools, and Geomechanics.io’s proprietary mining database, then reviewed for technical accuracy & edited by our geotechnical team.

Related Articles

Related Industries & Products

Mining

Geotechnical software solutions for mining operations including CMRR analysis, hydrogeological testing, and data management.

CMRR-io

Streamline coal mine roof stability assessments with our cloud-based CMRR software featuring automated calculations, multi-scenario analysis, and collaborative workflows.

HYDROGEO-io

Comprehensive hydrogeological testing platform for managing, analysing, and reporting on packer tests, lugeon values, and hydraulic conductivity assessments.

GEODB-io

Centralised geotechnical data management solution for storing, accessing, and analysing all your site investigation and material testing data.