Kumba UHDMS at Sishen: design, yield and LoM implications for process engineers

Reviewed by Joe Ashwell

First reported on International Mining – News

30 Second Briefing

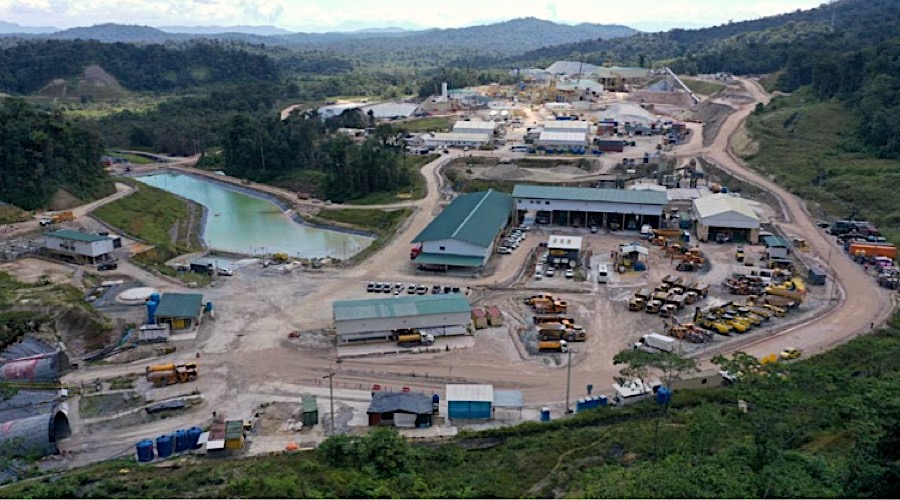

Kumba Iron Ore is investing ZAR11.2 billion (about US$600 million) to retrofit ultra-high-dense-media-separation (UHDMS) technology into the existing DMS plant at its Sishen mine in South Africa’s Northern Cape. The UHDMS circuit is designed to treat lower-grade ore and waste material at higher cut densities than conventional DMS, materially lifting product quality and overall yield. For process and plant engineers, the project signals a shift towards more intensive beneficiation to extend Sishen’s life of mine and improve margins without new pit development.

Technical Brief

- Retrofit focuses on upgrading the existing Sishen DMS plant rather than constructing a greenfield facility.

- UHDMS circuit is being integrated into current flowsheet to handle material previously classed as waste.

- Higher cut-density operation targets liberation of iron units from lower-grade, more contaminated ore streams.

- Project scheduling is aligned with Sishen’s medium- to long-term mine plan to smooth feed transitions.

- Brownfield tie-ins must maintain plant throughput during construction, implying staged commissioning and parallel running.

- Process control upgrades will be critical to manage tighter density windows and media stability at ultra-high SG.

- UHDMS adoption at Sishen provides a reference for similar brownfield beneficiation upgrades in mature iron ore districts.

Our Take

Within our 120 iron ore‑tagged pieces, South African items are relatively sparse compared with Australia and Brazil, so a large UHDMS rollout at Sishen signals that the Northern Cape is still attracting tier‑one brownfield capital despite rail and export bottlenecks.

An investment of around USD 600 million at Kumba Iron Ore’s Sishen mine is at the upper end of brownfield upgrade spends in our mining database, suggesting UHDMS is being treated as a core value-preservation tool to extend asset life rather than a marginal debottlenecking exercise.

For iron ore projects in our coverage, margin-focused processing upgrades like UHDMS tend to be followed by mine plan revisions and reserve reclassification, so peers in South Africa may face pressure to revisit low-grade stockpiles and waste dumps as potential feed.

Prepared by collating external sources, AI-assisted tools, and Geomechanics.io’s proprietary mining database, then reviewed for technical accuracy & edited by our geotechnical team.

Related Articles

Related Industries & Products

Mining

Geotechnical software solutions for mining operations including CMRR analysis, hydrogeological testing, and data management.

Construction

Quality control software for construction companies with material testing, batch tracking, and compliance management.

CMRR-io

Streamline coal mine roof stability assessments with our cloud-based CMRR software featuring automated calculations, multi-scenario analysis, and collaborative workflows.

HYDROGEO-io

Comprehensive hydrogeological testing platform for managing, analysing, and reporting on packer tests, lugeon values, and hydraulic conductivity assessments.

GEODB-io

Centralised geotechnical data management solution for storing, accessing, and analysing all your site investigation and material testing data.